Electric Motor

Electric motors are the workhorses of modern technology, converting electrical energy into mechanical power through the fascinating interplay of magnetic fields and electric currents. Here's a breakdown of how they function and their key components, designed especially for web designers looking to understand the mechanics behind these essential devices:

Basic Principle: Electric motors harness the power of electromagnetism, where the movement of a conductor in a magnetic field generates a force, causing motion. This principle, known as the Lorentz force, is at the core of how electric motors operate.

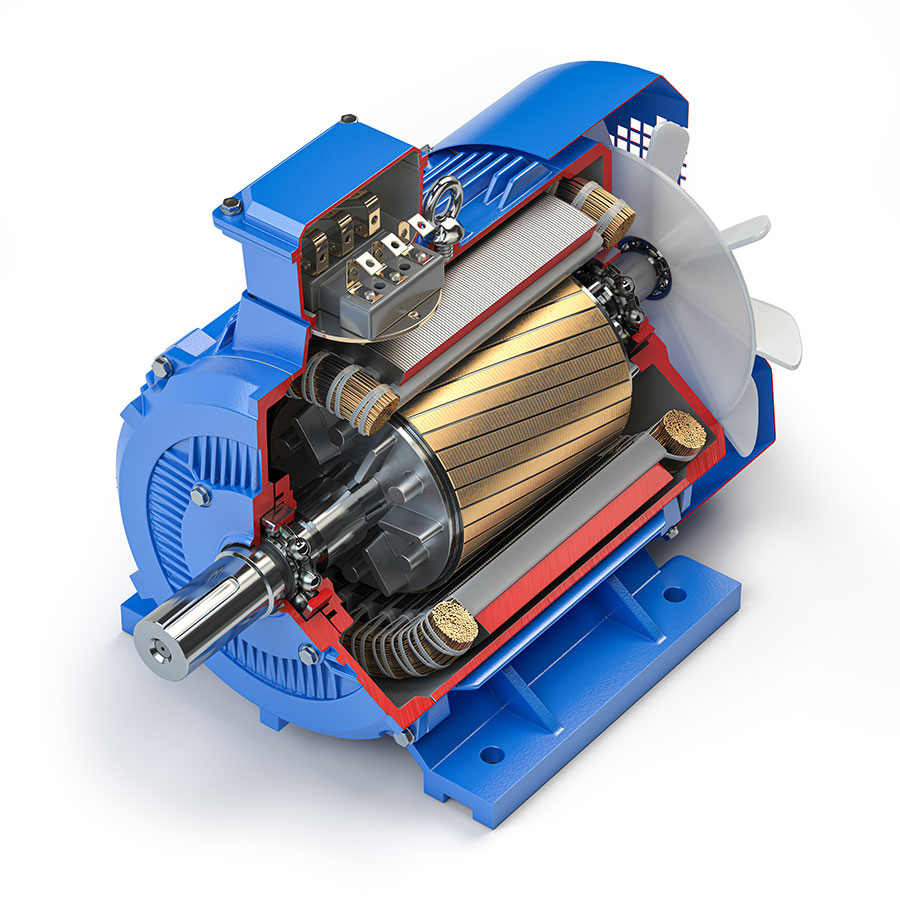

Key Components:

- Stator: This stationary part creates a magnetic field using coils or windings wrapped around a ferromagnetic core.

- Rotor: The rotating part experiences the force from the magnetic field and can be either a permanent magnet or an electromagnet.

- Shaft: Connects the rotor to external loads or mechanical systems, transmitting the mechanical energy produced by the motor.

- Bearings: These support and facilitate the smooth rotation of the shaft within the motor housing.

- Enclosure: Protects internal components from environmental factors like dust, moisture, and debris, ensuring long-term durability and reliability.

Types of Electric Motors:

- DC Motors: Operate on direct current and are widely used in applications requiring variable speed control, such as electric vehicles and robotics.

- AC Motors: Run on alternating current and are commonly found in household appliances, HVAC systems, and industrial equipment.

- Induction Motors: These robust AC motors have a rotor induced by the stator's magnetic field, offering reliability and versatility.

- Synchronous Motors: Known for their precise speed control, these motors operate at a fixed speed determined by AC frequency.

- Brushless DC Motors (BLDC): Highly efficient and low maintenance, BLDC motors are favoured in electric vehicles and drones for their performance and reliability.

High Speed Synchronous Motors

swipe horizontally to read more

| Ratings | Supply | Mounting |

|---|---|---|

| 1,000 to 20,000 kW | 2000 to 13800 Volts | Horizontal |

| 4 to 8 Pole | 50 or 60 Hertz | Vertical |

Enclosures

- Totally Enclosed Fan Cooled (TEFC)

- Totally Enclosed Water to Air Cooled (TEWAC)

- Open Drip Proof (ODP)

- NEMA WP-II

Low Speed Synchronous Motors

swipe horizontally to read more

| Ratings | Supply | Mounting |

|---|---|---|

| 3,000 to 20,000 kW | 2000 to 13800 Volts | Horizontal |

| 10 to 48 Pole | 50 or 60 Hertz | - |

Enclosures

- Totally Enclosed Fan Cooled (TEFC)

- Totally Enclosed Water to Air Cooled (TEWAC)

- Open Drip Proof (ODP)

- NEMA WP-II

Squirrel Cage Motors

swipe horizontally to read more

| Ratings | Supply | Mounting |

|---|---|---|

| 75 to 20,000 kW | 1000 to 13800 Volts | Horizontal |

| 2 to 20 Pole (others available) | 50 or 60 Hertz | Vertical |

Enclosures

- Totally Enclosed Fan Cooled (TEFC)

- Totally Enclosed Water to Air Cooled (TEWAC)

- Open Drip Proof (ODP)

- NEMA WP-II

Wound Rotor Induction Motors

swipe horizontally to read more

| Ratings | Supply | Mounting |

|---|---|---|

| 200 to 10,000 kW | 1000 to 13800 Volts | Horizontal |

| 4 to 12 Pole (Others Available) | 50 or 60 Hertz | Vertical |

Enclosures

- Totally Enclosed Fan Cooled (TEFC)

- Totally Enclosed Water to Air Cooled (TEWAC)

- Open Drip Proof (ODP)

- NEMA WP-II