At Calcutta Belt Centre, we manufacture premium SHR (Super Heat Resistant) Grade Rubber Conveyor Belts specifically engineered to excel in extreme high-temperature applications where conventional conveyor belts fail. Our SHR grade belts represent advanced materials technology designed to maintain structural integrity, flexibility, and operational reliability when handling materials at temperatures up to 200°C, making them indispensable for steel plants, foundries, cement kilns, and other high-temperature industrial processes throughout Eastern India.

Advanced Heat-Resistant Technology

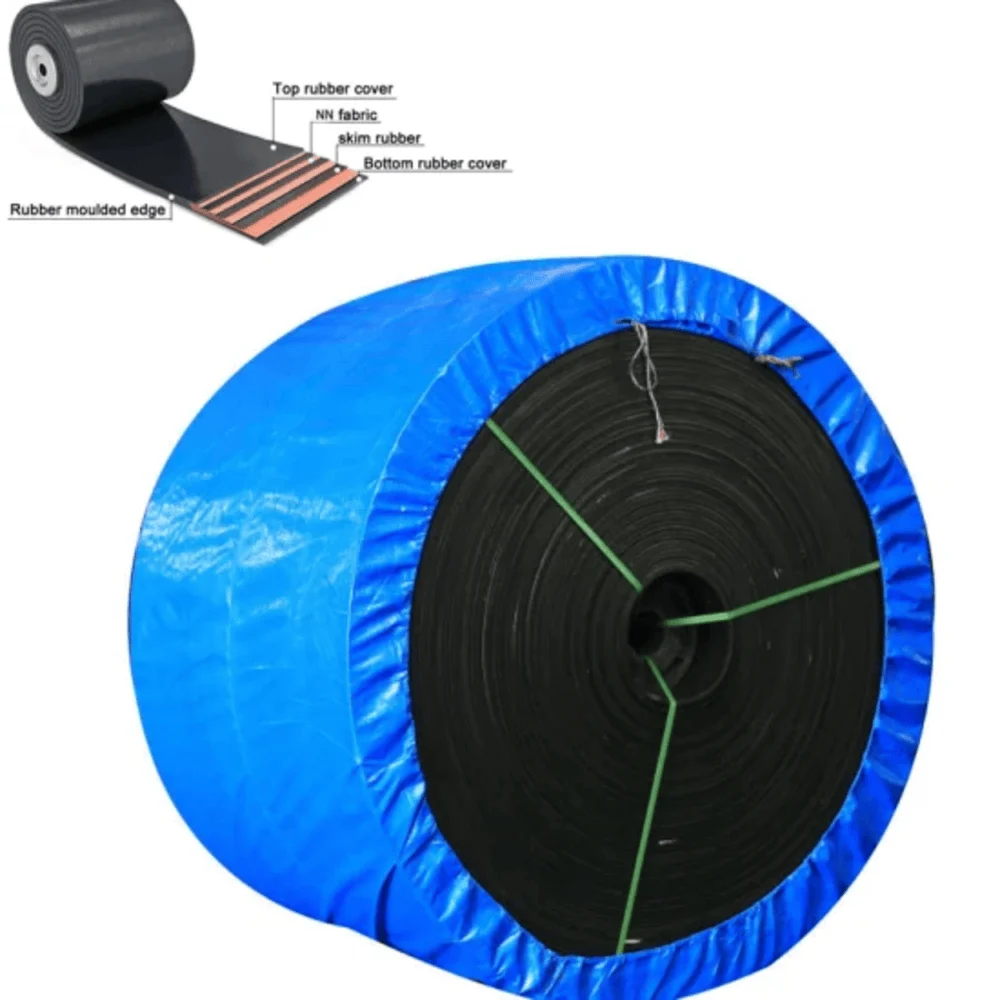

Our SHR grade conveyor belts incorporate specially formulated heat-resistant rubber compounds utilizing advanced polymer chemistry and reinforcement technologies. The sophisticated construction features synthetic rubber blends with exceptional thermal stability, specialized heat-resistant fabric reinforcement maintaining strength at elevated temperatures, advanced antioxidants and heat stabilizers preventing degradation, and proprietary compounding techniques ensuring uniform heat distribution and dissipation. This technology enables sustained operation in temperatures that would rapidly deteriorate standard rubber belts, providing reliable performance in the most demanding thermal environments.

Superior Thermal Performance

These belts deliver outstanding thermal resistance through continuous operating capability at temperatures up to 200°C without structural degradation, excellent thermal shock resistance handling rapid temperature fluctuations, superior heat aging characteristics maintaining flexibility and strength over extended high-temperature exposure, enhanced thermal conductivity facilitating heat dissipation and preventing hot spot formation, and exceptional resistance to thermal cracking and hardening common in high-temperature applications. Our SHR grade compounds maintain critical physical properties including tensile strength, elongation, and impact resistance even under prolonged heat exposure.

Specialized Applications

SHR grade conveyor belts excel in steel plant applications including hot sinter transport from sintering plants, hot coke handling in coke oven operations, slag and hot material transport in steel-making processes, foundry applications handling hot castings and molten metal byproducts, cement industry applications including hot clinker transport from rotary kilns, glass manufacturing handling hot glass materials and furnace products, power plant ash handling systems managing hot bottom ash and fly ash, and chemical processing applications involving heated materials and thermal processing operations. Each application benefits from customized compound selection optimized for specific temperature ranges and material characteristics.

Quality Standards and Specifications

Our SHR grade belts are manufactured to stringent international standards with comprehensive testing protocols including heat aging tests confirming performance at rated temperatures, flame resistance testing meeting industrial safety requirements, thermal shock resistance validation ensuring reliability under temperature cycling, and mechanical property testing verifying strength retention at elevated temperatures. Available in widths from 400mm to 2400mm with various ply constructions and specialized surface treatments for specific applications.

Calcutta Belt Centre provides complete SHR grade solutions including expert application engineering, precision installation services coordinated with high-temperature system commissioning, specialized maintenance programs designed for thermal environments, and comprehensive technical support ensuring optimal performance in extreme temperature conditions across Eastern India's heavy industrial sectors.

Rubber Conveyor Belt Standard

| Standard | Region |

|---|---|

| DIN 22102 | German |

| AS 1333 | Australian |

| SABS | South African |

| RMA | US, South America |

| BS 490 | British |

| JS | Japanese |

Industries We Serve

Industries We Serve

RMC Plant

Cement Industries

Mining Industries

Sand And Gravel

Stone Crusher

Cement Plant

Our Global Presence

Our Global Presence

India India |

Japan Japan |

Russia Russia |

United States United States |

Saudi Arabia Saudi Arabia |

Kuwait Kuwait |

Singapore Singapore |

Malaysia Malaysia |

UAE UAE |

Germany Germany |

Italy Italy |

China China |

UK UK |

Canada Canada |

Iran Iran |

Thailand Thailand |

Oman Oman |

Australia Australia |

Qatar Qatar |

Mexico Mexico |

Brazil Brazil |

France France |

South Africa South Africa |

Jordan Jordan |

Spain Spain |

Hong Kong Hong Kong |

Netherlands Netherlands |

Indonesia Indonesia |

South Korea South Korea |

Turkey Turkey |

Morocco Morocco |

Costa Rica Costa Rica |

Kazakhstan Kazakhstan |

Philippines Philippines |

Egypt Egypt |

Vietnam Vietnam |

Myanmar Myanmar |

Venezuela Venezuela |

Taiwan Taiwan |

Nigeria Nigeria |

Bangladesh Bangladesh |

Iraq Iraq |

Ukraine Ukraine |

Poland Poland |

Romania Romania |

Cyprus Cyprus |

Angola Angola |

Colombia Colombia |

Norway Norway |

Chile Chile |

Tobago Tobago |

Greece Greece |

Czechia Czechia |

Belgium Belgium |

Sri Lanka Sri Lanka |

Portugal Portugal |