Tyre Coupling

Characteristics of Tyre Coupling

Following are some of the characteristics of Tyre Coupling:

- Power is transmitted by a Rubber with superior elasticity

- Possible transmit the power fully under misalignment.

- Be smoothly Transmitted the Power

- Low noise and High durability

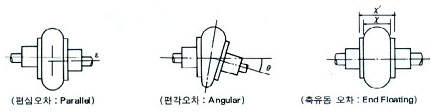

- PARALLEL

The movement of the grid in the lubricated grooves in Tyre Coupling accommodates parallel misalignment and steel permits full functioning of the grid-groove action in damping out shock and vibration. - ANGULAR

Under angular misalignment, the grid groove design permits a rocking and sliding action of the lubricated grid and hubs without any loss of power through the resilient grid. - AXIAL

End Float for both driving and driven members is permitted because the grid slides freely in the lubricated grooves. - TORSIONAL FLEXIBILITY

Torsional flexibility is the advantage of WCC Taper Grid Coupling, providing flexible accommodation to changing load conditions.

SUPERIOR FLEXIBILITY

Absorption of mechanical vibration

- Power is transmitted by a Rubber with superior elasticity.

- Possible transmit the power fully under misalignment.

- Be smoothly transmitted the power.

- Low noise.

- High durability.

- It is excellent to absorb the mechanical vibration and shock load.

- Fail-safe mechanism

- Parallel misalignment (¥å): 1% of Rubber Out Dia.

- Angular misalignment (¥è): 6% of Rubber Out Dia.

- End floating (¥ö¡¯-¥ö): 2% of Rubber Out Dia.

SIMPLE CONSTRUCTION

- Rapid and easy assembly/disassembly without moving any connected equipment .

- Simple maintenance.

- Less inventory Convenient inventory.

NO NEED LUBRICATION

- Not necessary to lubricate.

- Safe. No sparkling & no risk of fire due to friction.

POSSIBLE TO USE ANY CONDITION.

- Anti-oil, water, fume, dust and insulation.